View Our Certifications and Training

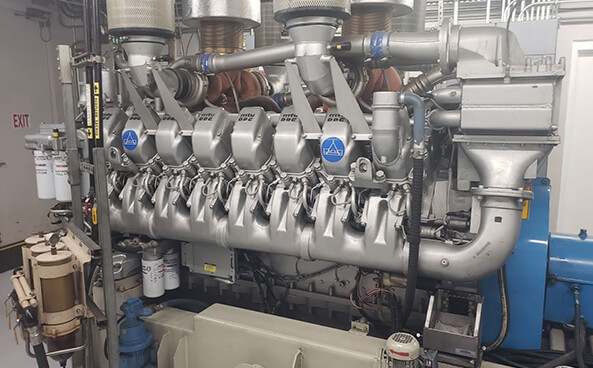

Our technicians at Logan Marine & Industrial Diesel LLC in Palm Bay, FL are highly trained and very knowledgeable in their respective fields. Our team has 30 years of quality, hands-on experience, including schooling on a number of engines. We specialize in Series 50, 53, 60, 71, 92, 149, 2000, 4000 and many more!

Training

- General Environmental, Safety and Health Certification OSHA Standard

- Hazard Communication OSHA Standard Title 29 CFR 1910.1200

- Lockout OSHA Standard Title 29 CFR 1910.147 Energy Control

- Tagout Certification OSHA Standards 29 CFR 1910.147

Experience

- “A” Class Diesel Mechanic with a Major Industrial and Marine Engine Company

- Head Mechanic and Fleet Manager of a Major Corporation

- Marine Technician

- Service Shop Supervisor of an International Company

Affiliations

Member of Palm Bay Chamber of Commerce

Certifications

Admiralty Service

Ford Diesel Engine (1060/1460) for Fleets

Course Training

- Design and Function of the Engine

- Disassembling and Assembling of the Engine

- Exchange of all Components

- Execution of Maintenance Tasks

- Explanation of Air, Fuel, Lube and Cooling Systems

- Explanation of Fluids and Lubricants Specification

- Handling of Documentation

Series 2000 Service

Series 2000CR Service M1/M

MTU Electronics Service Tools/E-3

Series 60 M1/M+M3 Overhaul

Course Training

- Design and Function of the Engine

- Execution of the Maintenance Tasks up to QL2

- Explanation of Air, Fuel, Lube and Cooling Systems

- Explanation of Fluids and Lubricants Specification

- Handling of Documentation

- Replacement of the Subassemblies

- Troubleshooting

Series 2000 Overhaul

Service Tools E3

Course Training

- Adapting Parameter Sets and System Software to Target Systems

- Communicating With Related Systems Using Data Links (CAN, RS 422, RS 232)

- Configuring and Connecting the Dialog Unit to Various Related Systems

- Design, Functions and Operations “DIASYS” Version 2

- Handling Parameter Change Information; Play Back Parameter Sets

- Operating MTU Server for Downloading; Software via Modems (EPROM Database)

- Programming PIM and PPS Node Numbers

- Recording and Evaluating Measurement Data

- Testing and Changing Parameters, Curves and Characteristics

- Using Programs for Testing CAN and Serial Interfaces

- Using the Backup Data Module BDM. Programming “MEM-5” Memory Modules, MPU-23 Cards

ADEC E3

Course Training

- Component Replacement

- Design of Systems

- Function Description

- Handling of Dialogue

System or Servicing Tools

- Inspection of

Components and Systems

- Operation of

Electronic Systems

- Presentation of the

Scope of Electronic Equipment

- Schematics and

Documentation

- Troubleshooting of

Fault Codes

- (DDC 8880) DDEC III, IV and V

- (DDC8879) Series 60 EGR

- DDEC III and IV Automotive

- M1/E ADEC/M

- Marine DDEC Troubleshooting

Course Training

- Design and Function of Smartline and Blueline

- Design and Function of the ECU-7

- Explanation of Parameters

- Handling of Dialogue System Diasys 2.52 and Service Tools

- Handling of Documentation and Drawings

- Replacement of Components

- System Check

M1/E MDEC/M

Course Training

- CAN Communication

- Component Replacement

- Download of Engine and Plant Data (EPROM)

- Explanation of Diasys 2.Xx (Actual Version)

- Explanation of the Engine Wiring and Sensors

- Handling of Dialog Unit

- Introduction of Blueline/MCS-5 Type 1.Operation of the LOP

- Introduction to the Engine Management System

- System Testing

- Troubleshooting

Series 4000-03 Update

Course Training

- Design and Function of the Engine

- Execution of Maintenance Tasks up to QL2

- Explanation of Air, Fuel, Lube and Cooling Systems

- Design and Function of the Engine

- Execution of Maintenance Tasks up to QL2

- Explanation of Air, Fuel, Lube and Cooling Systems

As seen, we are highly experienced in the field.